This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Willy-Brandt-Platz, Germany

ProjectWilly-Brandt-PlatzLocationBerlin, GermanyLighting DesignLicht Kunst Licht, GermanyArchitectWES LandschaftsArchitektur, GermanyAdditional DesignWES LandschaftsArchitektur Berlin (Landscape Planning)ClientFlughafen Berlin BrandenburgLighting SuppliersWE-EFPhotographyFrieder Blickle / WE-EF

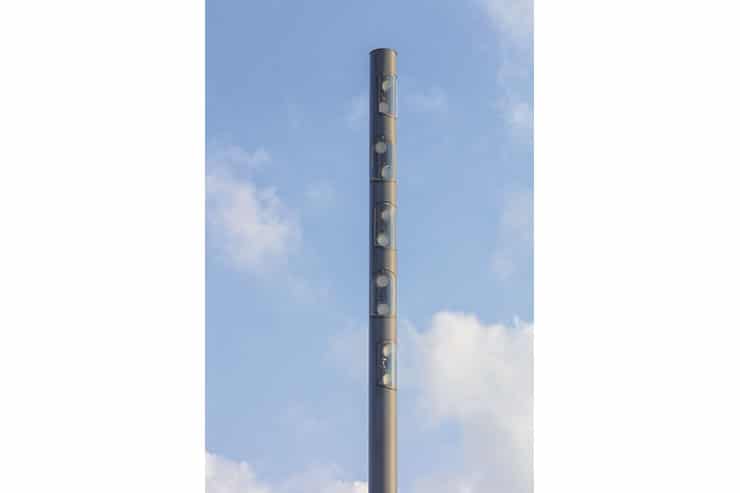

Willy-Brandt-Platz, in front of Terminal 1, is the architectural centre of the new Berlin Brandenburg Airport. In 2015, the long construction period necessitated a new approach to the forecourt lighting due to changed requirements and regulations. Licht Kunst Licht developed an impressive concept – the approximately 14,000 square metres of the vast forecourt are fully illuminated, but without seeming sterile thanks to a soft progression in the levels of brightness. This is achieved by two rows of lighting, each consisting of four 16-metre-high light columns around the edges of the new forecourt.

A project of this size cannot be realised with “off the peg” products. The planners’ idea of integrating the entire lighting technology into the slender columns also posed a challenge for WE-EF. The columns are made of a single piece of hot-dip galvanized steel tube and have been given a project-specific special coating in the colour “DB703 micaceous iron ore”. The tube diameter of 300 mm has enough room for the compact FLC141 LED projectors, which are mounted in pairs and one above the other with special fastening pins in a tube cut-out. The openings have flush acrylic glass covers and are axially offset to allow the projectors to be optimally aligned. The top three cut-outs are used for general lighting, while the bottom two provide emergency lighting for the area that is used as an assembly point for the terminal in the event of an emergency.

For the differentiated illumination of the forecourt, the lighting designers benefited from the availability of WE-EF’s FLC141 projectors in a uniform design with different light distributions. The traffic zones at the edge are accentuated and the illuminance decreases continuously towards the centre of the square. Furthermore, wide-beam optics illuminate the areas at the edges and very narrow-beam optics beam light over the square. The emergency lighting works in a similar way, but combines wide-beam and medium-beam light distributions to meet the normative requirements for illuminance and uniformity at defined assembly points.

During an on-site trialling procedure a lifting platform conveyed a tube section fitted with projectors to the planned mounting height as a mock-up to gain realistic visual impressions and measuring values. The light columns are anchored in the normal way (like floodlight masts) with flanges bolted to concrete foundations. In contrast, other logistical aspects were quite different to standard processes. For example, WE-EF employees fitted the projectors and the electrics in the light columns directly on site before they were subsequently installed in their respective positions.

Even though the lighting of Willy-Brandt-Platz is just one aspect of the whole BER project, it is the first impression of the airport for many users and visitors – and it shows how even exceptional challenges in a project can be mastered with intelligent planning and professional partners.