This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

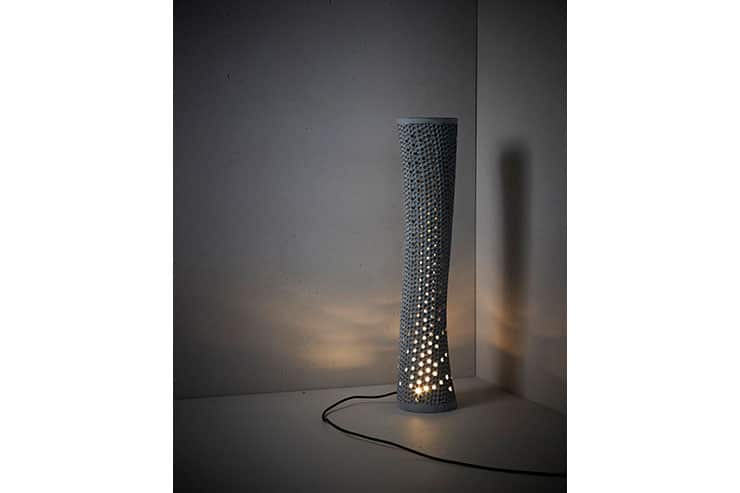

Bolla - Cemento

ProductBollaManufacturerCementoDesignerHagenHinderdael

Pairing product design with art, the designers Lisa Hinderdael and Sofia Hagen merge their abilities as architectural designers with the material knowledge and craftsmanship of local artisans and cutting-edge technology. Producing elements that push the boundaries of engineering whilst bearing the incentive of a continuous afterlife.

HagenHinderdael believe that design has the responsibility to educate and inform – providing clever solutions to real world challenges. Designed in collaboration with Cemento UK for the Milan Design Week Guiltless Plastic challenge, BOLLA brings awareness to how the escalated use of packaging materials is affecting our environment.

Landfills can’t cope with the quantities of plastic being deposited – some of it poisonous and most of it non-degradable. Pointing the way to a circular economy instead of designing things to fail, bubble wrap sourced from packaging waste is used as formwork and transformed through parametric modelling and innovative research into the light product BOLLA.

The concept began with material research into concrete and its ability to provide a backdrop for recycling plastic and packaging waste. Experimenting with sculptural forms that had never before been made in concrete, this research developed into a light sculpture that would be organic in form with a thin-walled exterior and hiding within it a series of technological advancements in design. Manufactured with a CNC mould, and housing slimline OLED technology, BOLLA captures the essence of “waste not, want not” – creating an innovative and sustainable new light product.

Working with material scientists at Cemento UK, a custom-aggregate has been developed in which recycled plastic particles are combined into a concrete mixture and poured into the organic mould. This aggregate can be further enhanced through the addition of various pigments; allowing BOLLA to be customised to match any interior.

Pushing the research further, BOLLA’s requirement to be a light source led to additional material studies – investigating the porosity of the concrete shell as a means to spread light. The light output was to achieve a striking, effervescent glow coming from within the concrete. With an integrated LED source and using a script inspired by the very piece of packaging from which our design process began, we developed a perforated pattern that would capture the texture of bubble wrap and disperse a uniform light across BOLLA.

Our material research and process pushed us to an end product that is not only eco-friendly, but fully degradable – such that if it breaks, it can be sent back to our manufacturers where the concrete shell will be ground and reused for a new light production. This allows BOLLA to avoid its materials ending up back in a landfill – and brings our narrative full circle with the HagenHinderdael ethos of a continuous afterlife. Allowing for each light to be produced at low impact yet giving it a unique bespoke character through the nature of the materials used.

BOLLA’s first prototype comes as a floor standing light at 700mm height, with the possibility to be transformed into a pendant or wall light as required.